Machine and Equipment

"Quality is our dignity." With the help of high-class equipment, CTi’s highly automated process is able to remain quality not only steady but also efficient. The machines used in our cable productions are mostly imported from countries which are best known for “quality”, including Germany/ UK/ USA/ Japan/ Switzerland, etc. Therefore, CTi also values strict on-line quality control to achieve our clients’ quality expectation.

|

Copper Drawing Machine (Niehoff)Draw the copper conductor to the requird specification. |

|

Tri-layer wire insulation machine (Maillefer)Tri-layer wire insulation machine (Maillefer) |

Conductor Bunching MachineTwist a set of copper conductors to form a bunched/stranded conductor. |

|

Double Twist Machine (Northampton)Multiple pairs of insulated conductors are twisted to form an assembly. |

|

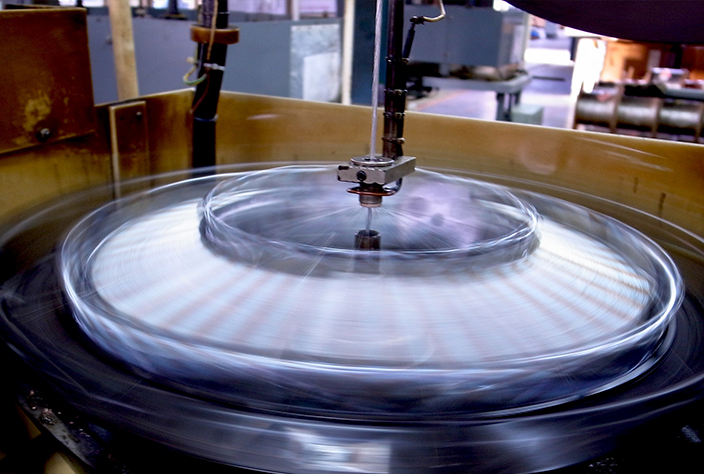

Braiding MachineShield the cables with braided wires. |

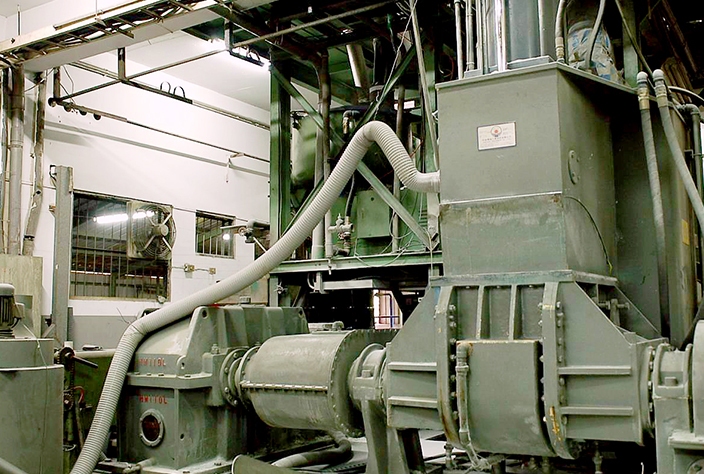

Compounding MachineMix and compound the formulation to form plastic pellets of consistent shape and size. |

|

Jacket Extrusion MachineEncase the cables with jacketing material. |

|

Clean Room FacilityBio-burden controlled air/water circulation and production environment. |

Cable Cutting MachineTo cut the cable into specific length. |

Japan Made Robot ArmAutomated production procedure for HDMI. |

Connector ProductionDie-casting / injection-molding |

256 bit SSL Encryption

256 bit SSL Encryption